Future prospects for stainless steel suppliers

Current market overview

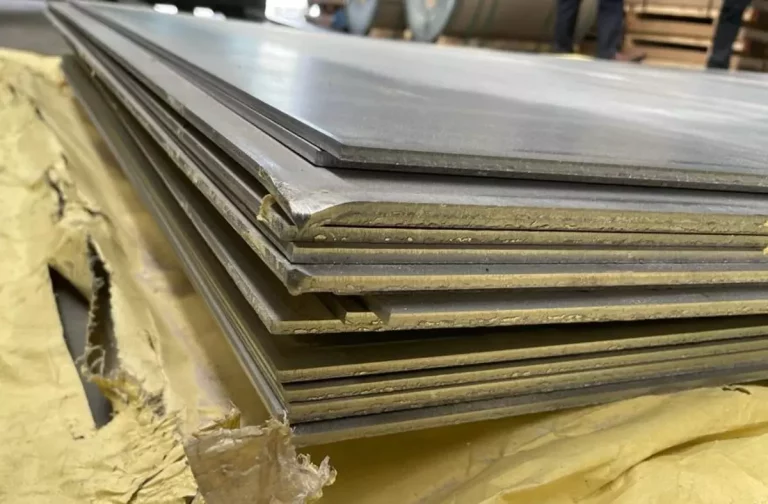

Stainless steel, known for its durability, corrosion resistance, and aesthetic appeal, remains a vital material in various industries.

The global demand for stainless steel has been steadily increasing, driven by sectors such as construction, automotive, and household appliances. Suppliers are adapting to the changing market dynamics, focusing on enhancing production capabilities and ensuring quality to meet the diverse needs of their customers.

The COVID-19 pandemic significantly impacted the stainless steel market, causing disruptions in the supply chain and fluctuations in demand. However, the market is gradually recovering, with increasing investments in infrastructure projects and a resurgence in manufacturing activities. Stainless steel suppliers are now exploring innovative strategies to capitalize on emerging opportunities and mitigate future risks.

Technological advancements in production processes have also played a crucial role in shaping the current market landscape. Suppliers are investing in automation, digitalization, and sustainable practices to improve efficiency and reduce environmental impact. These advancements are expected to further boost the competitiveness of stainless steel in the global market.

Emerging trends in stainless steel production

The stainless steel industry is witnessing several emerging trends that are likely to influence its future trajectory. One significant trend is the increasing focus on sustainability. As environmental concerns gain prominence, stainless steel suppliers are prioritizing eco-friendly production methods and the use of recycled materials. This shift not only aligns with global sustainability goals but also enhances the market appeal of stainless steel products.

Another notable trend is the adoption of advanced manufacturing technologies. Techniques such as additive manufacturing (3D printing) and precision engineering are being integrated into the production processes. These technologies enable the creation of complex designs, reduce material wastage, and enhance overall production efficiency. Suppliers embracing these innovations are well-positioned to cater to the evolving demands of their clients.

Moreover, the industry is experiencing a growing emphasis on customization. End-users are seeking tailored stainless steel solutions that meet their specific requirements. Suppliers are responding by offering a wide range of grades, finishes, and dimensions. This trend towards customization is driving suppliers to develop flexible production capabilities and foster closer collaborations with their customers.

Opportunities in renewable energy

The renewable energy sector presents significant growth opportunities for stainless steel suppliers. As the world transitions towards cleaner energy sources, the demand for materials that can withstand harsh environmental conditions is increasing. Stainless steel, with its excellent resistance to corrosion and high temperatures, is a preferred choice for applications in solar, wind, and hydroelectric power generation.

In solar energy, stainless steel is used in components such as mounting structures, fasteners, and frames. Its durability ensures long-term performance, even in extreme weather conditions. Wind energy projects also rely on stainless steel for turbine components, ensuring structural integrity and reliability. The growing investments in renewable energy infrastructure are expected to drive the demand for stainless steel significantly.

Furthermore, stainless steel suppliers are exploring opportunities in emerging technologies such as hydrogen energy. The development of hydrogen fuel cells and storage systems requires materials that can withstand high pressure and corrosive environments. Stainless steel’s unique properties make it an ideal candidate for these applications, positioning suppliers to tap into this expanding market.

Challenges facing stainless steel suppliers

Despite the promising prospects, stainless steel suppliers face several challenges that could impact their growth. One major challenge is the volatility of raw material prices. The prices of key inputs, such as nickel and chromium, are subject to fluctuations due to market dynamics and geopolitical factors. These variations can affect the production costs and pricing strategies of suppliers.

Another challenge is the increasing competition from alternative materials. Advances in material science have led to the development of new materials that offer comparable or superior properties to stainless steel. For instance, composites and advanced alloys are gaining traction in industries traditionally dominated by stainless steel. Suppliers need to continuously innovate and highlight the unique advantages of stainless steel to stay competitive.

Additionally, regulatory compliance and environmental regulations pose challenges for stainless steel suppliers. Stricter emission norms and sustainability standards require significant investments in technology and infrastructure. Suppliers must navigate these regulatory landscapes while maintaining profitability and ensuring compliance with global standards.

Strategic partnerships and collaborations

To navigate the complexities of the market and seize growth opportunities, stainless steel suppliers are increasingly forming strategic partnerships and collaborations. These alliances enable suppliers to leverage each other’s strengths, share technological advancements, and expand their market reach. Collaborations with research institutions and industry associations also facilitate the development of innovative solutions.

Joint ventures with companies in complementary industries are another avenue for growth. For example, partnerships with construction firms can lead to the co-development of specialized stainless steel products for building applications. Similarly, collaborations with automotive manufacturers can result in the creation of advanced materials for vehicle components, enhancing performance and safety.

Moreover, suppliers are exploring partnerships with recycling companies to ensure a steady supply of recycled stainless steel. This not only supports sustainability goals but also helps in reducing dependence on raw materials. Such strategic initiatives are crucial for enhancing competitiveness and driving long-term growth in the stainless steel industry – https://rollsteel.eu.

The role of innovation in future growth

Innovation is a key driver of future growth for stainless steel suppliers. The development of new alloys with enhanced properties, such as improved strength, ductility, and corrosion resistance, opens up new applications and markets. Research and development efforts are focused on creating stainless steel grades that meet the evolving demands of various industries.

Digital transformation is also playing a significant role in the innovation landscape. The adoption of smart manufacturing technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), is revolutionizing production processes. These technologies enable real-time monitoring, predictive maintenance, and optimization of operations, resulting in increased efficiency and reduced downtime.

Furthermore, innovation in product design and applications is expanding the possibilities for stainless steel. Suppliers are exploring new uses in fields such as healthcare, aerospace, and electronics. By staying at the forefront of technological advancements and continuously improving their product offerings, stainless steel suppliers can ensure sustained growth and relevance in the global market.

The future prospects for stainless steel suppliers are promising, driven by emerging trends, opportunities in renewable energy, and the strategic importance of innovation. While challenges such as raw material price volatility and competition from alternative materials exist, suppliers that adapt to market changes and invest in sustainable practices are well-positioned for success.

Strategic partnerships and collaborations, along with a focus on customization and advanced manufacturing technologies, are key strategies for growth. By leveraging these approaches, stainless steel suppliers can enhance their competitiveness and meet the diverse needs of their customers in an ever-evolving market.

Ultimately, the stainless steel industry is set to thrive in the coming years, with suppliers playing a crucial role in supporting global infrastructure development, technological advancements, and the transition to a more sustainable future. As they navigate the challenges and capitalize on the opportunities, stainless steel suppliers will continue to be integral to various sectors and industries worldwide.